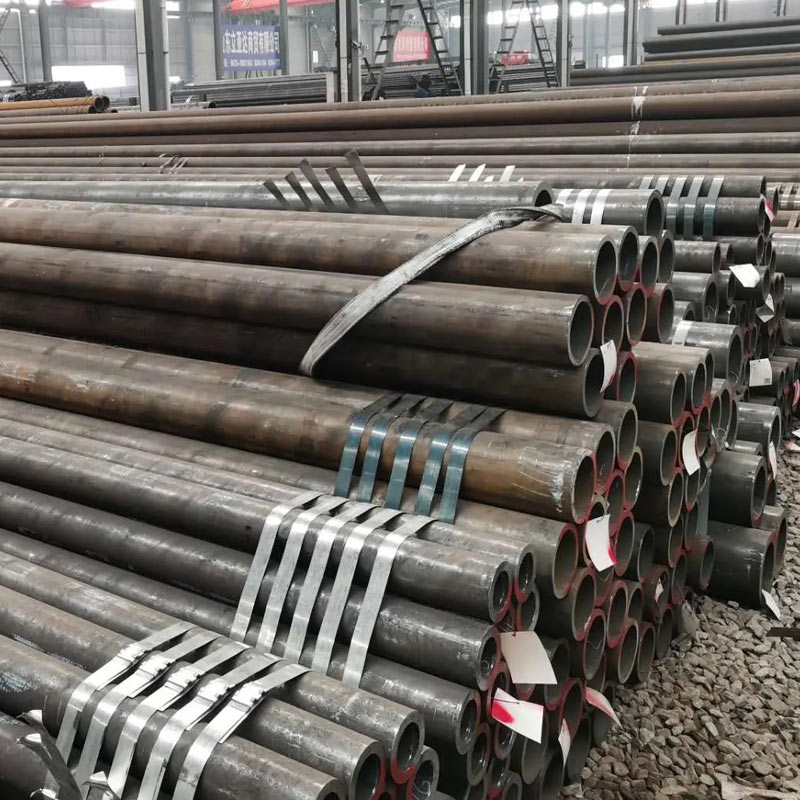

ASTM A106 GR.B Mild Hot Finished Seamless Carbon Steel Pipe

Short Description:

ASTM A106 GR.B Mild Hot Finished Seamless Carbon Steel Pipe are used in industrial applications involving high temperatures, including process piping, boiling units, compression stations, and oil refineries. The extra silicon improves the product’s performance in high temperature environments, such as steam piping and process applications. ASTM/ASME/SA106 Piping (also included in ASME Code SA/A106) is the standard specification for seamless carbon steel piping in high temperature environments. It is most commonly used in refineries and factories when gases or fluids are transported at high temperature and pressure.

Haihui Steel is the world leader in the supply of A106/SA106 pipe, stocking a full line of Grade B/C pipes in sizes ranging from NPS 1/2″ to NPS 36″ with nominal (average) wall thicknesses as specified in ANSI B36.10 Show. Other sizes of pipe may be supplied if the pipe meets all other requirements of this specification.

Pipe ordered in accordance with this specification shall be suitable for bending, flanging, welding and similar forming operations. A full range of SA/A106 stock is available in Annexes 10 to 160, STD, XS, XXS.

Size(mm):

| OD(Out Diameter) | W.T(Wall Thickness) | L(Length) |

| 6.0-323 | 1.0-30.0 | max 12000 |