There are various schedules to these pipes as they handle various levels of pressures. There are usually sch 80, 100, 120, 140 and 160 that have heavy walls. The heavy wall thickness seamless pipe can sometimes be double extra strong and is denoted as XXS or XXS. The material can vary as there are different grades of carbon steel that are used to make the different thick wall carbon steel pipe types. The high volume, high flow, high pressure systems like oil and gas transmission lines, water lines, and power plant cooling systems all used different types,

Thick-walled seamless steel pipes are mainly used in water conservancy, petrochemical, chemical, electric power, agricultural irrigation, urban construction and other industries. For liquid transport: water supply and drainage. Gas transportation: natural gas, steam, liquefied petroleum gas. Structural uses: used as bridge piling pipes; docks, roads, buildings and other structures.

The key to the quality of thick-walled steel pipes should be thickness uniformity. Uncontrolled wall thickness of thick-walled steel pipes directly affects the quality and practicability of steel pipes, thick-walled steel pipes, and large-diameter seamless steel pipes. It is generally used for various processing and thick-walled parts processing. ,, the uniform wall thickness of the steel pipe will directly affect the quality of the post-processing parts, the wall of the thick-walled steel pipe is not controlled, and the overall quality of the steel is not strict.

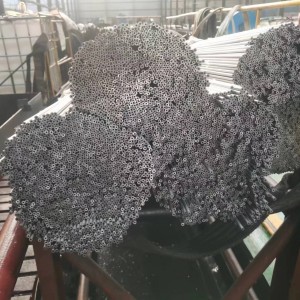

Thick-walled steel pipes refer to steel pipes with a pipe diameter to wall thickness ratio of less than 20. Mainly used for petroleum geological drill pipes, petrochemical cracking pipes, boiler pipes, bearing pipes and high-precision structural pipes for automobiles, tractors and aviation. The quality of thick-walled seamless steel pipes depends on the uniformity of wall thickness.